Patternmaking Overview

What is Patternmaking?

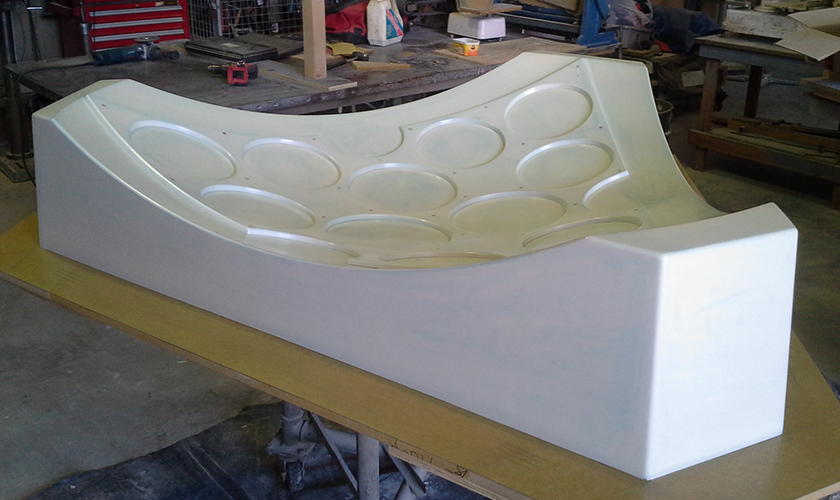

The pattern shop is usually the starting point for the production of tooling for a wide variety of industries such as foundries, vacuum forming, plastic injection, fibreglass and concrete products. Patterns are manufactured in timber, plastic or metal, depending on the application.

A patternmaker obtains his qualification through a four year apprenticeship, which includes formal learning periods at TAFE and the remainder of the indenture in a pattern shop under the tutelage of a mentor tradesman. As his knowledge and skills increase, he is able to produce more technical patterns.

A pattern is first an idea, which becomes a sketch or technical drawing. Using a wide variety of hand tools and machinery a dimensionally accurate pattern or tool is produced.

The modern patternmaker's workshop is a world of big boys toys, with lathes, sanding disks, band saws and modern technology seeping in. Gone are the leather fillets of yesteryear, with a wide variety of resins, heat resistant fillers and other new products, combined with computer tools like CAD and email, today's patternmaker is at home "on the bench" or behind a computer.